A peek into what happened and what’s next in robotics

Peer written with Irati Zamalloa Ugarte.

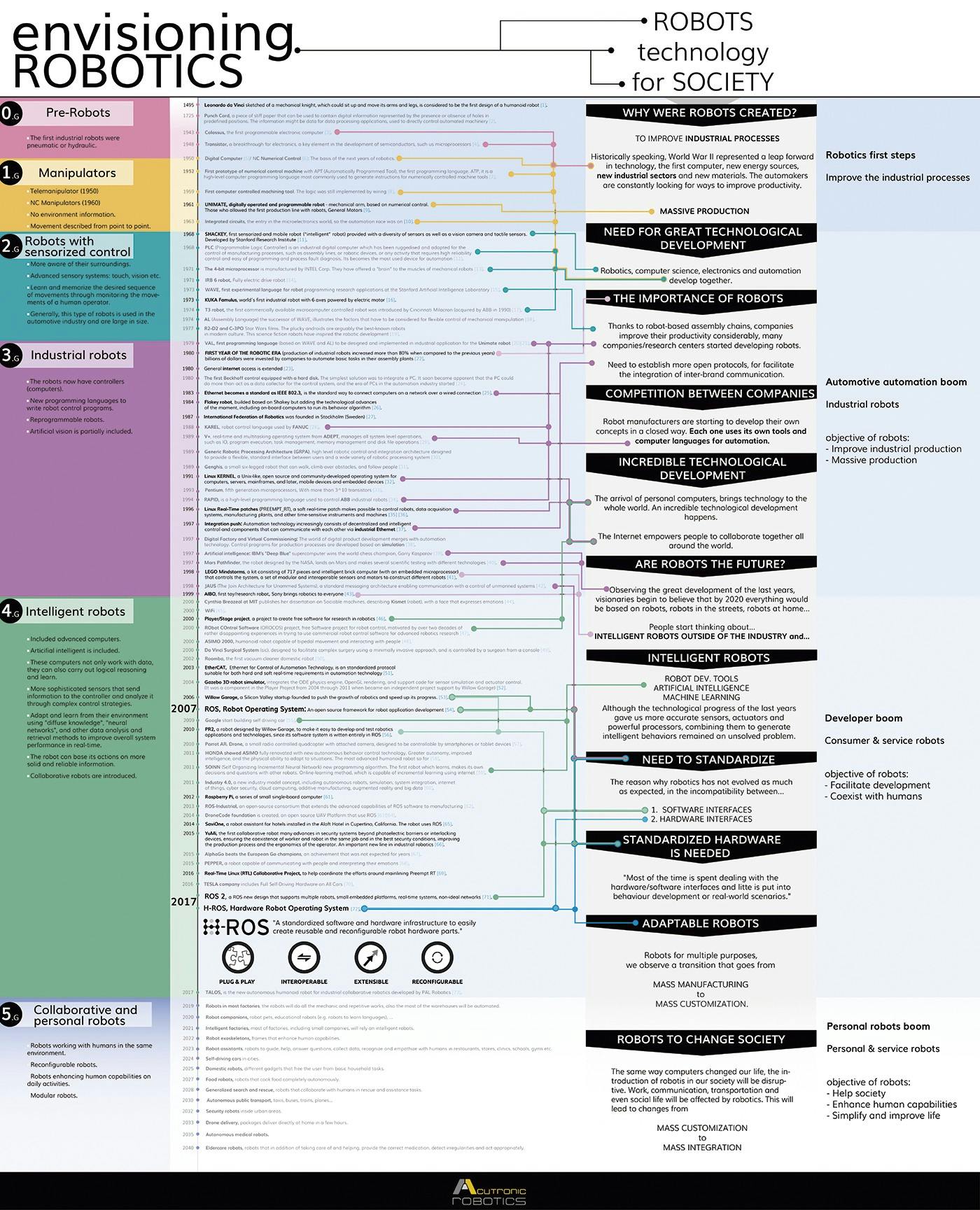

Robotics is called to be the next technological revolution. Many seem to agree that robots will have a tremendous impact over the following years and some are heavily betting on it. Companies are investing billions in buying others and public authorities are discussing legal frameworks to enable a coherent growth of robots.

Understanding where the field of robotics is heading is more than guesswork. While much of the existing public concerns focus on discussing the potential issues that will arise with the advent of robots, in this article, we present a review of some of the most relevant milestones that happened in robotics over the last decades and our insight about the technologically feasible near future of robotics.

Pre-Robots and first manipulators

What’s the origin of robots? To figure it out we’ll need to look quite a few decades ago where different conflicts motivated the technological growth that eventually enabled companies to build the first digitally controlled mechanical arms to boost the performance obtained while executing different activities. One those first and well documented robots was UNIMATE (considered by many the first industrial robot), a programmable machine funded by General Motors used to create a production line with only robots. UNIMATE helped improve the production at the time. This motivated other companies and research centers to actively dedicate resources to robotics which boosted the growth of the field.

Sensorized robots

Sensors were not typically included in robots until the 70’s. Starting from 1968, a second generation of robots appeared which integrated sensors. These robots were able to react to its environment and offer responses that met different scenarios.

Relevant investments were observed during this period in robotics. Industrial players all around the world were attracted by the advantage that robots promised.

Worldwide industrial robots — Era of robots

Many consider that the Era of Robots started in 1980. Billions of dollars were invested by companies all around to world to automate basic tasks in their assembly lines and sales of industrial robots grew 80% above what happened in previous years.

Key technologies for the future of robots appeared within these years. General Internet access was extended in 1980, Ethernet became a standard in 1983 (IEEE 802.3), the Linux kernel was announced in 1991 and soon after that real-time patches started appearing on top of Linux.

The robots created between 1980 and 1999 belong to what we call the third generation of robots. Robots that were reprogrammable and included dedicated controllers. Robots populated many industrial sectors and were used for a wide variety of activities: painting, soldering, moving, assembling, etc.

By the end of the 90s, companies started thinking about robots outside of the industrial environment. Several companies created promising concepts that later will represent an inspiration for future roboticists. Among the robots created within this period, we highlight two:

- The first LEGO Mindstorms kit (1998), a set consisting of 717 pieces including LEGO bricks, motors, gears, different sensors, and a RCX Brick with an embedded microprocessor to construct various robots using the exact same parts. The kit allowed to teach the principles of robotics. Creative projects have appeared over the years showing the potential of interchangeable hardware in robotics. Within a few years the LEGO Mindstorms kit became the most successful project that involved robot part interchangeability.

- Sony’s AIBO (1999), the world’s first entertainment robot. Widely used for research and development, Sony brought robotics to everyone with a $1,500 robot that included a distributed hardware and software architecture. The OPEN-R architecture involved the use of modular hardware components — e.g. appendages that can be easily removed and replaced to change the shape and function of the robots — , and modular software components that can be interchanged to modify their behavior and movement patterns. OPEN-R represented an inspiration for future robotic frameworks and showed promise to minimize the need for programming individual movements or responses.

Both products made use of interchangeable hardware and software modules however these efforts have never been translated to industrial environments.

Integration effort was identified as one of the main issues within robotics and particularly related to robots operating in industry. A common infrastructure typically reduces the integration effort by facilitating an environment where components can simply be connected and interoperate. Each of the infrastructure-supported components are optimized for such integration at their conception and the infrastructure handles the integration effort. At that point, components could come from different manufacturers, yet when supported by a common infrastructure, they will interoperate.

Sony’s AIBO and LEGO’s Mindstorms kit were built upon this principle and both presented common infrastructures. Even though they came from the consumer side of robotics, one could argue that their success was strongly related to the fact that both products made use of interchangeable hardware and software modules. The use of a common infrastructure proved to be one of the key advantages of these technologies however those concepts were never translated to industrial environments. Instead, each manufacturer, in an attempt to dominate the market started creating their own “robot programming languages”.

Dawn of smart robots

Starting from the year 2000, we observed that a new generation of robot technologies started appearing. The so called fourth generation of robots consisted of more intelligent robots that included advanced computers to reason and learn (to some extend at least) and more sophisticated sensors that helped controllers adapt themselves more effectively to different circumstances.

Among the technologies that appeared in this period we’d highlight the Player Project (2000, formerly the Player/Stage Project), the Gazebo simulator (2004) and the Robot Operating System (2007). Moreover, relevant hardware platforms appeared during these years. Single Board Computers (SBCs) like the Raspberry Pi enabled millions of users all around the world to create robots easily.

The boost of bio-inspired Artificial Intelligence

The increasing popularity of artificial intelligence and particularly of neural networks became relevant in this period as well. While a lot of the important work on neural networks happened in the 80’s and in the 90’s, at that time computers did not have enough computational power. Datasets weren’t big enough to be useful in practical applications. As a result, neural networks practically disappeared in the first decade of the 21st century. However, starting from 2009 (speech recognition), neural networks gained popularity and started delivering good results in fields such as computer vision (2012) or machine translation (2014). During the last years we’ve seen how these techniques have been translated to robotics for tasks such as robotic grasping. In the coming years it’s expected to see how these AI techniques will have more and more impact in robotics.

What happened to industrial robots?

Relevant key technologies appeared also for the industrial robotics landscape (e.g.: EtherCAT) however except for the appearance of the first so called collaborative robots, the progress within the field of industrial robotics has significantly slowed down when compared to previous decades. Several groups identified this fact and wrote about it with conflicting opinions. Below we summarize some of the most relevant points encountered while reviewing previous work:

-

The Industrial robot industry — is it only a supplier industry?For some, the industrial robot industry is a supplier industry. It supplies components and systems to larger industries, mainly, the manufacturing industry. These groups argue that the manufacturing industry is dominated by the PLC, motion control and communication suppliers which together with the big customers are setting the standards. Industrial robots thereby need to adapt and speak factory language (PROFINET, ETHERCAT, Modbus TCP, Ethernet/IP, CANOPEN, DEVICENET, etc.) which for each factory, might be different.

-

**Lack of collaboration and standardized interfaces in industry**To the date, each industrial robot manufacturer’s business model is somehow about locking you into their system and controllers. Typically one will encounter the following facts when working with an industrial robot: a) each robot company has its own proprietary programming language, b) programs can’t be ported from one robot company to the next one, c) communication protocols are different, d) logical, mechanical and electrical interfaces are not standardized across the industry.As a result, most robotic peripheral makers suffer from having to support many different protocols which requires a lot of development time that doesn’t add functionality to the product.

-

**Competing by obscuring vs opening new markets?**The close attitude of most industrial robot companies is typically justified by the existing competition in this environment. Such an attitude leads to a lack of understanding between different manufacturers and solutions but in exchange it apparently secures clients and favours competition.An interesting approach would be to have manufacturers agree on a common infrastructure. Such an infrastructure could define a set of electrical and logical interfaces (leaving the mechanical ones aside due to the variability of robots in different industries) that would allow industrial robot companies to produce robots and components that could interoperate, be exchanged and eventually enter into new markets. This would also lead to a competing environment where manufacturers will need to demonstrate features rather than the typical obscured environment where only some are allowed to participate.

The Hardware Robot Operating System (H-ROS)

For robots to enter new and different fields, it seems reasonable that they need to adapt to the environment itself. This fact was previously highlighted for the industrial robotics case where robots had to be fluent with factory languages. One could argue that the same for service robots (e.g. households robots that will need to adapt to dish washers, washing machines, media servers, etc.), medical robots and many other areas of robotics. Such reasoning leads to the creation of the Hardware Robot Operating System (H-ROS), a vendor-agnostic hardware and software infrastructure for the creation of robot components that interoperate and can be exchanged between robots. H-ROS builds on top of ROS which is used to define a set of standardized logical interfaces that each physical robot component must meet if compliant with H-ROS.

H-ROS facilitates a fast way of building robots choosing the best component for each use-case from a common robot marketplace. It complies with different environments (industrial, professional, medical, …) where variables such as time constraints are critical. Building or extending robots is simplified to the point of placing H-ROS compliant components together. The user simply needs to program the cognition part (i.e. brain) of the robot and develop their own use-cases without facing the complexity of integrating different technologies and hardware interfaces.

H-ROS is on active development and the first prototypes are being deployed with partners. If you’re interested to learn more about it refer to http://h-ros.com or drop us a line at contact@acutronicrobotics.com.

The future ahead

With latest AI results being translated to robotics and the recent investments in the field, there’s a high expectation for what’s coming to robotics over the following decades.

As it was nicely introduced by Melonee Wise in an interview not long ago, nowadays, still, there’re not that many things you can do with a $1000-5000 BOM robot (which is what most people would pay on an individual basis for a robot). Hardware is still a limiting factor and our team strongly believes that a common infrastructure such as H-ROS will facilitate an environment where robot hardware and software will be able to evolve.

The list presented above summarizes, according to our judgement, some of the most technically feasible future robotic technologies to appear.

Acknowledgments

This review was funded and supported by Acutronic Robotics, a firm focused on the development of next-generation robot solutions for a range of clients.

The authors would also like to thank the Erle Robotics and the Acutronic groups for their support and help.

References

- [1] Gates, B. ”A robot in every home,” Scientific American, 296(1), 2007, pp. 58–65. (link)

- [2] Trikha, B. “ A Journey from floppy disk to cloud storage,” in International Journal on Computer Science and Engineering,Vol. 2, 2010, pp.1449–1452. (link)

- [3] Copeland, B. J. “Colossus: its origins and originators,” in IEEE Annals of the History of Computing, Vol. 26, 2004, pp. 38–45. (link)

- [4] Bondyopadhyay, P. K. “In the beginning [junction transistor],” in Proceedings of the IEEE, Vol. 86, 1998, pp.63–77. (link)

- [5] Bryson, A. E. “Optimal control-1950 to 1985,” in IEEE Control Systems, Vol. 16, 1996, pp.26–33. (link)

- [6] Middleditch, A. E. “Survey of numerical controller technology,” in Production Automation Project, University of Rochester, 1973. (link)

- [7] Acal, A. P., & Lobera, A. S. “Virtual reality simulation applied to a numerical control milling machine,” in International Journal on Interactive Design and Manufacturing, Vol.1, 2007, pp.143–154. (link)

- [8] Mark, M. “U.S. Patent №2,901,927,” Washington DC: U.S. Patent and Trademark Office, 1959 (link)

- [9] Mickle, P. “A peep into the automated future,” in The capital century 1900–1999. http://www. capitalcentury. com/1961. html, 1961. (link)

- [10] Kilby, J. S. (1976). Invention of the integrated circuit. IEEE Transactions on electron devices, 23(7), 648–654. (link)

- [11] Giralt, G., Chatila, R., & Vaisset, M. “An integrated navigation and motion control system for autonomous multisensory mobile robots,” in Autonomous robot vehicles, 1990, pp.420–443. (link)

- [12] Bryan, L. A., & Bryan, E. A. “Programmable controllers,” 1988. (link)

- [13] Wade, J. “Dynamics of organizational communities and technological bandwagons: An empirical investigation of community evolution in the microprocessor market,” in Strategic Management Journal, Vol.16, 1995, pp.111–133. (link)

- [14] Wallén, J. “The history of the industrial robot,” in Linköping University Electronic Press, 2008. (link)

- [15] Paul, R. P., “WAVE: A Model Based Language for Manipulator Control,” in The Industrial Robot, Vol. 4, 1977, pp.10–17. (link)

- [16] Shepherd, S., & Buchstab, A. “Kuka robots on-site,” in Robotic Fabrication in Architecture, Art and Design 2014, 2014, pp. 373–380. (link)

- [17] Cutkosky, M. R., & Wright, P. K. (1982). Position Sensing Wrists for Industrial Manipulators (No. CMU-RI-TR-82–9). CARNEGIE-MELLON UNIV PITTSBURGH PA ROBOTICS INST. (link)

- [18] Finkel, R., Taylor, R., Bolles, Paul, R. and Feldman, J., “An Overview of AL, A Programming System for Automation,” in Proceedings -Fourth International Joint Conference on Artificial Intelligence, June 1975, pp.758–765. (link)

- [19] Park, J., & Kim, G. J. “Robots with projectors: an alternative to anthropomorphic HRI,” in Proceedings of the 4th ACM/IEEE international conference on Human robot interaction, March 2009, pp. 221–222 (link)

- [20] Srihari, K., & Deisenroth, M. P. (1988). Robot Programming Languages — A State of the Art Survey. In Robotics and Factories of the Future’87 (pp. 625–635). Springer Berlin Heidelberg. (link)

- [21] Gruver, W. A., Soroka, B. J., Craig, J. J. and Turner, T. L., “Industrial Robot Programming Languages: A Comparative Evaluation,” in IEEE Transactions on Systems, Man, and Cybernetics, Vol. SMC-14, №4, July/August 1984, pp. 565–570. (link)

- [22] Maeda, J. (2005). Current research and development and approach to future automated construction in Japan. In Construction Research Congress 2005: Broadening Perspectives (pp. 1–11). (link)

- [23] Castells, M. “The Internet galaxy: Reflections on the Internet, business, and society,” in Oxford University Press on Demand, 2002. (link)

- [24] Beckhoof “25 Years of PC Control,” 2011. (link)

- [25] Shuang Yu “IEEE 802.3 ‘Standard for Ethernet’ Marks 30 Years of Innovation and Global Market Growth,” Press release IEEE, June 24, 2013. Retrieved January 11, 2014. (link)

- [26] Brooks, R. “New approaches to robotics,”in Science, 253(5025), 1991, 1227–1232. (link)

- [27] World Heritage Encyclopedia, “International Federation of Robotics” in World Heritage Encyclopedia (link)

- [28] Lapham, J. “ RobotScript™: the introduction of a universal robot programming language,” Industrial Robot: An International Journal, 26(1),1999, pp. 17–25 (link)

- [29]García Marín, J. A. “New concepts in automation and robotic technology for surface engineering,” 2010. (link)

- [30] Walter A Aviles, Robin T Laird, and Margaret E Myers. “Towards a modular robotic architecture,” in 1988 Robotics Conferences. International Society for Optics and Photonics, 1989, pp. 271–278 (link)

- [31] Angle, C. “Genghis, a six legged autonomous walking robot,” Doctoral dissertation, Massachusetts Institute of Technology, 1989. (link)

- [32] Bovet, D. P., & Cesati, M. “Understanding the Linux Kernel: from I/O ports to process management,” in O’Reilly Media, Inc.” 2005. (link)

- [33] Alpert, D., & Avnon, D. “Architecture of the Pentium microprocessor,” in IEEE micro, Vol. 13, 1993, pp.11–21. (link)

- [34] Hollingum, J. “ABB focus on lean robotization,” in Industrial Robot: An International Journal, Vol. 21, 1994, pp.15–16. (link)

- [35] Barabanov, M. “A Linux Based Real-Time Operating System,” 1996. (link)

- [36] Yodaiken, V. “Cheap Operating systems Research,” in Published in the Proceedings of the First Conference on Freely Redistributable Systems, Cambridge MA, 1996 (link)

- [37] Decotignie, J. D. “Ethernet-based real-time and industrial communications,” in Proceedings of the IEEE, Vol. 93, 2005, pp.1102–1117. (link)

- [38] Wade, S., Dunnigan, M. W., & Williams, B. W. “Modeling and simulation of induction machine vector control with rotor resistance identification,” in IEEE transactions on power electronics, Vol. 12, 1997, pp.495–506. (link)

- [39] Campbell, M., Hoane, A. J., & Hsu, F. H. “Deep blue,” in Artificial intelligence, Vol. 134, 2002, pp.57–83. (link)

- [40] Folkner, W. M., Yoder, C. F., Yuan, D. N., Standish, E. M., & Preston, R. A. “Interior structure and seasonal mass redistribution of Mars from radio tracking of Mars Pathfinder,” in Science 278(5344), 1997, pp.1749–1752. (link)

- [41] Cliburn, D. C. “Experiences with the LEGO Mindstorms throughout the undergraduate computer science curriculum,”in Frontiers in Education Conference, 36th Annual,IEEE, October 2006, pp.1–6. (link)

- [42] Rowe S., R Wagner C. “An introduction to the joint architecture for unmanned systems (JAUS),” in Ann Arbor 1001, 2008. (link)

- [43] Fujita, M. “On activating human communications with pet-type robot AIBO,” in Proceedings of the IEEE, Vol. 92, 2004, pp.1804–1813.(link)

- [44] Breazeal, C. L. “Sociable machines: Expressive social exchange between humans and robots,” in Doctoral dissertation, Massachusetts Institute of Technology, 2000. (link)

- [45] Rafiei, M., Elmi, S. M., & Zare, A. “Wireless communication protocols for smart metering applications in power distribution networks,” in Electrical Power Distribution Networks (EPDC), 2012 Proceedings of 17th Conference on. IEEE, May 2012, pp. 1–5. (link)

- [46] Brian Gerkey, Richard T Vaughan, and Andrew Howard. “The Player/Stage project: Tools for multi-robot and distributed sensor systems” in Proceedings of the 11th international conference on advanced robotics. Vol. 1. 2003, pp. 317–323. (link)

- [47] Herman Bruyninckx. “Open robot control software: the OROCOS project” in Robotics and Automation, 2001. Proceedings 2001 icra. ieee International Conference on. Vol. 3. IEEE. 2001, pp. 2523–2528. (link)

- [48] Hirose, M., & Ogawa, K. “Honda humanoid robots development,” in Philosophical Transactions of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, 365(1850), 2007, pp.11–19. (link)

- [49] Mohr, F. W., Falk, V., Diegeler, A., Walther, T., Gummert, J. F., Bucerius, J., … & Autschbach, R. “Computer-enhanced “robotic” cardiac surgery: experience in 148 patients” in The Journal of thoracic and cardiovascular surgery, 121(5), 2001, pp.842–853. (link)

- [50] Jones, J. L., Mack, N. E., Nugent, D. M., & Sandin, P. E. “U.S. Patent №6,883,201,” in Washington, DC: U.S. Patent and Trademark Office, 2005. (link)

- [51] Jansen, D., & Buttner, H. “Real-time Ethernet: the EtherCAT solution,” in Computing and Control Engineering, 15(1), 2004, pp. 16–21. (link)

- [52] Koenig, N., & Howard, A. “Design and use paradigms for gazebo, an open-source multi-robot simulator,” in Intelligent Robots and Systems, 2004.(IROS 2004). Proceedings. 2004 IEEE/RSJ International Conference on IEEE., Vol. 3, September 2004, pp. 2149–2154. (link)

- [53] Cousins, S. “Willow garage retrospective [ros topics],” in IEEE Robotics & Automation Magazine, 21(1), 2014, pp.16–20. (link)

- [54] Garage, W. Robot operating system. 2009. [Online]. (link)

- [55] Fisher A. “Inside Google’s Quest To Popularize Self-Driving Cars,” in Popular Science, Bonnier Corporation, Retrieved 10 October 2013. (link)

- [56] Cousins, S. “Ros on the pr2 [ros topics],” in IEEE Robotics & Automation Magazine, 17(3), 2010, pp.23–25. (link)

- [57] PARROT, S. A. “Parrot AR. Drone,” 2010. (link)

- [58] Honda Motor Co. ASIMO, 2011. [Online]. (link)

- [59] Shen, F., Yu, H., Sakurai, K., & Hasegawa, O. “An incremental online semi-supervised active learning algorithm based on self-organizing incremental neural network,” in Neural Computing and Applications, 20(7), 2011, pp.1061–1074. (link)

- [60] Industria 4.0 en la Feria de Hannover: La senda hacia la “fábrica inteligente” pasa por la Feria de Hannover, sitio digital ‘Deutschland’, 7 de abril de 2014 (link)

- [61] Richardson, Matt, and Shawn Wallace “Getting started with raspberry PI,” in O’Reilly Media, Inc., 2012. (link)

- [62] Edwards, S., & Lewis, C. “Ros-industrial: applying the robot operating system (ros) to industrial applications,” in IEEE Int. Conference on Robotics and Automation, ECHORD Workshop, May 2012. (link)

- [63] Canis, B. Unmanned aircraft systems (UAS): Commercial outlook for a new industry. Congressional Research Service, Washington, 2015, p.8. (link)

- [64] Trishan de Lanerolle, The Dronecode Foundation aims to keep UAVs open, Jul 2015. [Online] (link)

- [65] Savioke, Your Robot Butler Has Arrived, August 2014. [Online]. (link)

- [66] ABB, “ABB introduces Yumi, world´s first truly collaborative dual-arm robot”, 2015. Press release (link)

- [67] LEE, Chang-Shing, et al. Human vs. Computer Go: Review and Prospect [Discussion Forum]. IEEE Computational Intelligence Magazine, 2016, vol. 11, no 3, pp. 67–72. (link)

- [68] Bogue, R. (2015). Sensors for robotic perception. Part one: human interaction and intentions. Industrial Robot: An International Journal, 42(5), pp.386–391 (link)

- [69] The Linux foundation, official wiki. 2009. [Online]. (link)

- [70] The Tesla Team, “ All Tesla Cars Being Produced Now Have Full Self-Driving Hardware” Official web, 19 Oct. 2016. [Online]. (link)

- [71] Brian Gerkey. Why ROS 2.0?, 2014. [Online]. (link)

- [72] Acutronic Robotics, “H-ROS: Hardware Robot Operating System”, 2016. [Online]. (link)

- [73] Judith Viladomat, TALOS:the next step in humanoid robots from PAL Robotics. 4 Oct. 2016 [Online]. (link)