Over the past 6 months, we benchmarked multiple tracking technologies for mobile, unpowered assets: construction gear, medical rentals, tools, shipping containers, and more. The goal: build a system that reliably tells you:

- Where is this item now?

- When was it last seen?

- What’s the cost per asset to do this at scale?

We tested:

- Cellular GPS (LandAirSea, Samsara)

- Passive/Active RFID (Zebra, Alien)

- BLE Trackers (Tile, One-Key, etc.)

- Apple AirTags + programmatic layer

Only one approach gave us:

- High-fidelity passive tracking

- Minimal labor

- Predictable location updates in the wild

- Sub-$4/month total cost

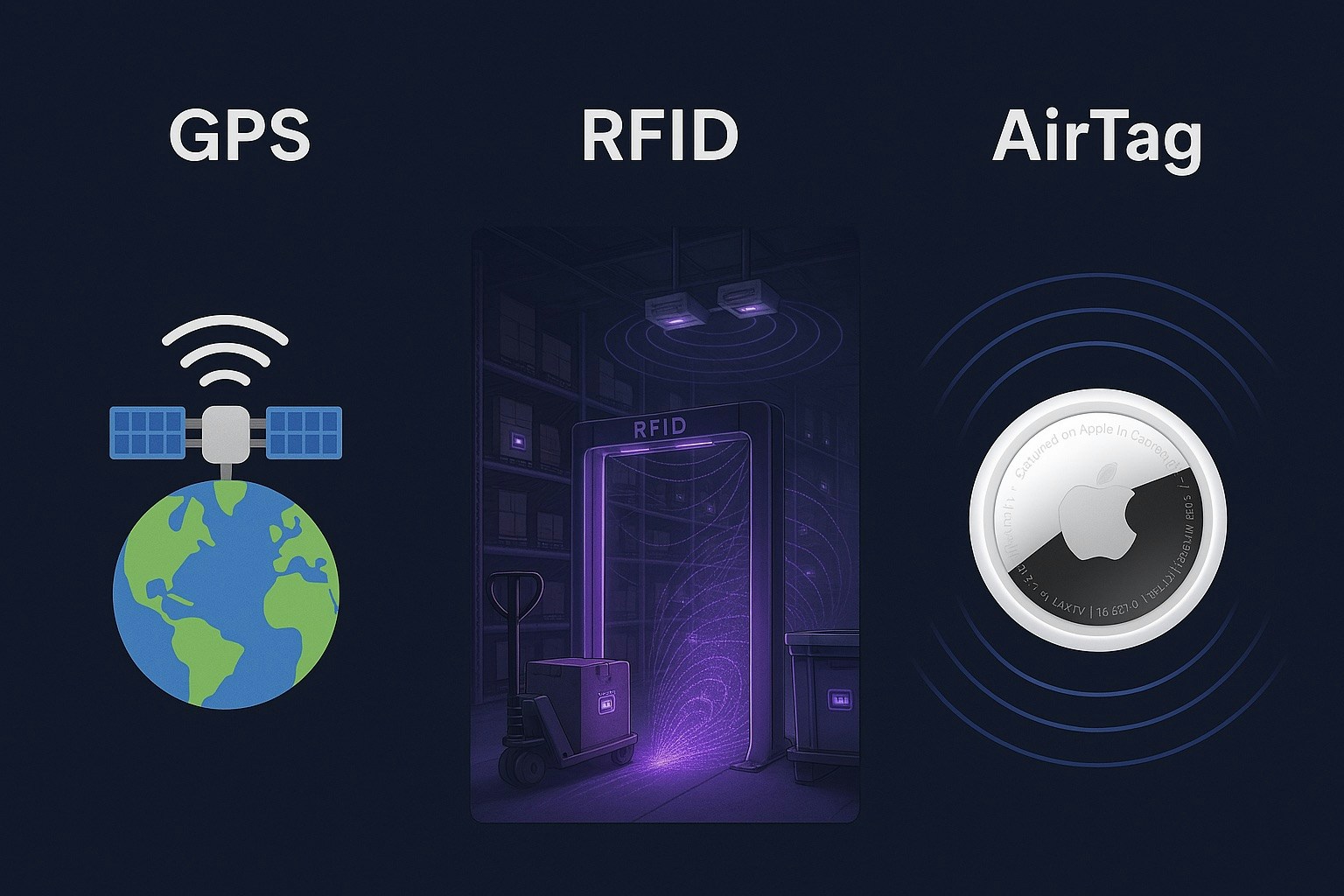

🔴 GPS Trackers — Power-Hungry & Operationally Fragile

lessCopyEdit[ Asset ]

|

[ GPS Module ]

|

[ LTE Modem ]---[ Carrier Network ]---[ Cloud Platform ]

|

[ Battery ]

What it’s good at:

- Real-time tracking when you have cell signal

- Fine-grained updates (every 10s–60s)

Failure modes in the field:

- Battery depletion → dead device in 7–30 days

- Indoor/urban canyons → GPS lock fails

- SIM provisioning → ~3% failure rate during setup

- Techs forget to charge or miswire installs

Measured in field:

- Avg install time (non-hardwired): 18 min

- Avg labor revisit per year: 5.7x

- Location latency indoors: >1hr or failed ping

GPS works for powered fleets. It breaks down hard for passive assets.

Annual TCO per device: ~$400 \ ($150 hardware + $240 data + $50 labor)

🟠 RFID — Great for Warehouses, Not the Field

lessCopyEdit[ RFID Tag ]---(Passive)---[ RFID Reader ]

|

[ Backend DB ]

Useful for:

- Inventory control at fixed chokepoints

- Bulk scanning in highly structured environments

Limitations:

- No real tracking — just “seen at gate X”

- Requires infrastructure at every decision point

- 0 coverage outdoors, in transit, on job sites

- Readers are expensive and fragile (EM interference prone)

Cost Breakdown:

-

Passive tags: $0.12–$0.80

-

Reader infrastructure/site: $2,500–$10,000

-

Integration overhead: high

Unless you control the entire environment, RFID creates visibility gaps you can't close.

Annual TCO (real deployments): $8k–$40k/site

🟡 BLE Trackers — “Tracking” That Usually Isn’t

cssCopyEdit[ BLE Beacon ] --x--> [ Needs Someone Running App ]

Examples tested:

- Tile Pro

- Milwaukee One-Key

- Chipolo Business Beta

Core issue: They rely on proprietary apps running in the background — no real mesh, just marketing.

Mesh Density (urban tests):

- Tile: 2 updates/week/asset in SF

- One-Key: 0 updates outside Milwaukee job sites

- Battery life: ~12 months (replaceable CR2032)

Key limitation:

If no one’s running the app, the device is invisible. In practice, that means ~99%+ dead zones.

No way to manage at scale. No geofences. No asset dashboard. Just a few stale pings, if you're lucky.

TCO: ~ $30–$60/year (still too high for something that barely works)

🟢 AirTags — When Paired with the Right Stack, They Win

lessCopyEdit[ AirTag ]---(BLE)---[ Any iPhone Nearby ]

|

[ Apple Find My Mesh ]

|

[ Programmatic Layer ]

|

[ AirPinpoint Dashboard ]

Key technical advantages:

- BLE beaconing interval: ~800ms (adaptive)

- U1 chip + BLE triangulation improves spatial accuracy

- Global passive mesh: 2.2B+ iOS devices relay encrypted updates

- Battery: 2–4 years on CR2032

- Range: We observed ~0.2–2.3 miles real-world handoff distance in cities

Test results:

- Urban ping latency: <8 minutes

- Suburban latency: ~12–45 minutes

- Dense indoor location accuracy: ~10–15m radius

- Deployment time: <60 seconds per asset

- No SIM, no charge cycles, no field config

This is the only BLE-based system with actual nationwide mesh reliability.

AirTag Comprehensive CR2032 Battery Brand Comparison

Based on extensive empirical testing of CR2032 batteries under conditions similar to AirTag operation, here's how different brands perform:

|

Brand |

Runtime (Hours) |

Runtime (Approx. Months)* |

Cost per Cell |

Value Rating (Hours/$) |

|---|---|---|---|---|

|

Panasonic |

1500 |

12.5 |

$1.04 |

1442 |

|

Voniko |

1448 |

12.1 |

$0.83 |

1745 |

|

Maxell |

1444 |

12.0 |

$0.58 |

2490 |

|

Toshiba |

1325 |

11.0 |

$0.64 |

2070 |

|

Harbor Freight |

1307 |

10.9 |

$0.75 |

1743 |

|

Energizer |

1307 |

10.9 |

$1.28 |

1021 |

|

Duracell |

1298 |

10.8 |

$1.81 |

717 |

|

AC Delco |

1223 |

10.2 |

$0.79 |

1548 |

|

Nightkonic |

1186 |

9.9 |

$0.24 |

4942 |

|

Murata |

1175 |

9.8 |

$0.45 |

2611 |

|

Hua Dao |

642 |

5.4 |

$0.14 |

4586 |

*Converted from accelerated test conditions to approximate real-world months based on typical AirTag usage patterns

Test Methodology: All batteries were tested with a consistent 80μA base load (approximately 16x the typical AirTag sleep current) with periodic higher current pulse loads similar to Bluetooth transmissions. Tests were normalized to account for minor variations in test fixtures.

🧮 Real Cost Comparison (Per 100 Assets, Per Year)

|

Tech |

Hardware |

Labor |

Subscriptions |

TCO (Year 1) |

|---|---|---|---|---|

|

GPS |

$15,000 |

$5,000 |

$36,000 |

$56,000 |

|

RFID |

$2,000 |

$4,000 |

$0 |

$6,000+ |

|

BLE |

$3,000 |

$3,000 |

$0 |

$6,000 |

|

AirTag + Platform |

$2,000 |

$500 |

$47.88 (flat) |

~$2,548 |

✅ Final Notes

AirTags on an ios device alone are not sufficient for business use. They lack:

-

Asset naming / grouping

-

Geofencing

-

Bulk management

-

Alerting / integrations

-

Silent mode (you don’t want customers getting “you’re being tracked” alerts)

But when paired with a 3rd party platform that solves those (like AirPinpoint) they become arguably the highest-leverage, lowest-friction tracking layer available for unpowered asset fleets.

If you’re trying to track equipment, rentals, forklifts, pumps, dollies, carts, containers, or anything that moves but doesn’t have power — this is the stack to beat.